- Institut de Recherche Dupuy de Lôme (IRDL), DGA, ACCIS

- Funds DGA

- Candidate : Melvin Josselin

- Academic guidance : Antoine le Duigou, Noelie Di Cesare, Mickael Castro and Fabrizio Scarpa

4D BIOMAT : 4D printing of novel reconfigurables structure made with biobased composites (2021-2024)

Context

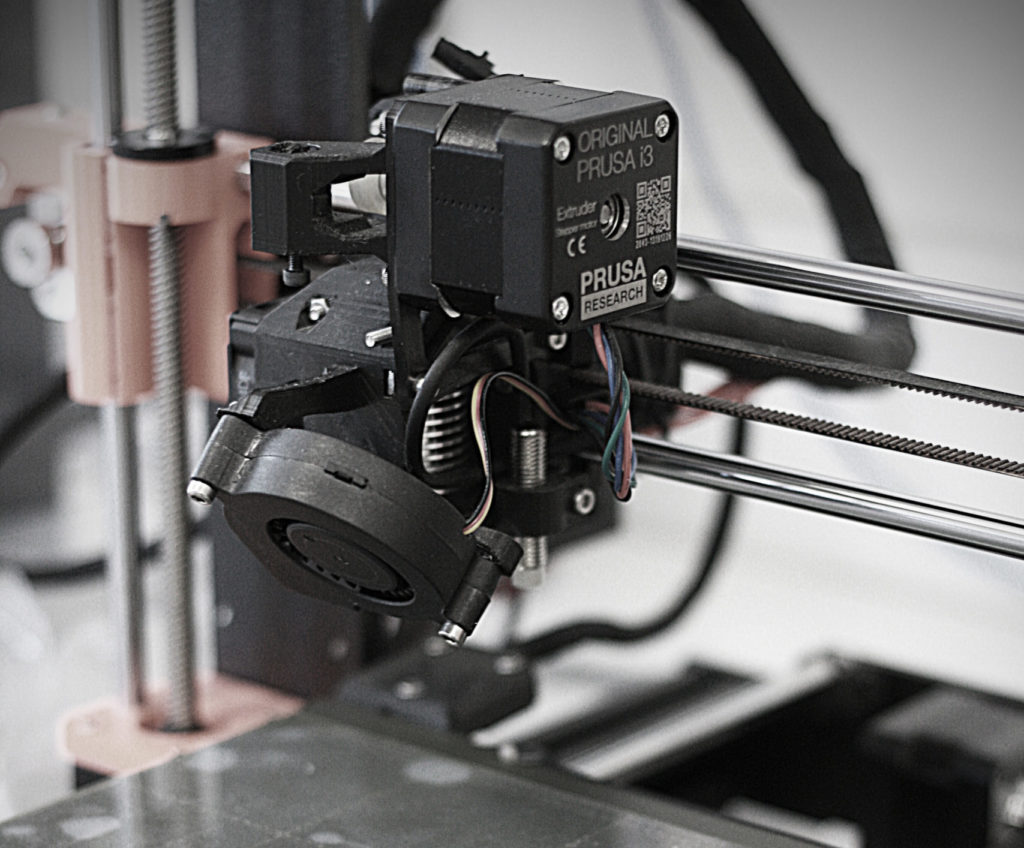

It is clear that the management of energy and resources are among the major challenges of innovation for tomorrow. Currently, solar trackers are platforms driven by electro-mechanical actuators to adapt the tilt of the solar panel to the path of the sun. Although this action can lead to better efficiency, it costs energy and requires maintenance which is detrimental in extreme environments such as hard to reach areas. In addition, sunflowers, well-known plants, know how to orient themselves towards the sun (heliotropism) and are a source of inspiration for the actuators of tomorrow [1]. The objective of the thesis project is to develop a new generation of reconfigurable structures for application in solar trackers from hygromorphic biocomposites produced by 4D printing. The hygromorphic biocomposites developed by the project leader since 2015 [2] [3] [4] are multifunctional materials (both sensors and actuators) inspired by biological structures (Fig 1a) which change shape autonomously (without input outside energy) under a variation of humidity thanks to their architecture in bimetallic form (Fig 1b).

To architect these new materials, additive manufacturing technologies such as 4D printing are preferred. According to Tibbits [5], it is the ability to program materials so that they change shape and properties under the effect of a stimulus. Thus, insofar as the printed parts have the function of sensors and actuators, part of the chain of command can be eliminated, thus reducing their failure. The objective of the thesis is to develop adaptive structures reacting to variations in humidity and temperature by proposing a directional response. Their design is inspired by heliotropic biological structures (eg Sunflower) and uses parametric / topological optimization tools, their formulation is based on the use of local renewable resources (biocomposites from polymer and plant fibers) while the 4D printing is used to control the pre-determined architecture.

References :

[1] JP. Vandenbrinka, Browna E, Harmerb S, Blackmana B. Turning heads: The biology of solar tracking in sunflower. Plant Sci 2014;224:20–6. [2] Le Duigou A, Castro M. Moisture-induced self-shaping flax-reinforced polypropylene biocomposite actuator. Ind Crops Prod 2015;71. doi:10.1016/j.indcrop.2015.03.077. [3] Le Duigou A, Requile S, Beaugrand J, Scarpa F, Castro M. Natural fibres actuators for smart bio-inspired hygromorph biocomposites. Smart Mater Struct 2017;26. doi:10.1088/1361-665X/aa9410. [4] Le Duigou A, Keryvin V, Beaugrand J, Pernes M, Scarpa F, Castro M. Humidity responsive actuation of bioinspired Hygromorph BioComposites (HBC) for adaptive structures. Comp Part A Appl Sci Manuf 2019;116:36–45. [5] Tibbits S. 4D Printing: Multi‐Material Shape Change. Arch Des 2014;84:116–21. doi:https://doi.org/10.1002/ad.1710.