- Institut de Recherche Dupuy de Lôme (IRDL)

- Funds (Brittany region)

- Candidate : Guillaume Chabaud

- Academic guidance : Antoine le Duigou and Mickael Castro

3D and 4D printing of high-performance continuous synthetic and natural fiber composites for structural applications and morphing (2017-2020)

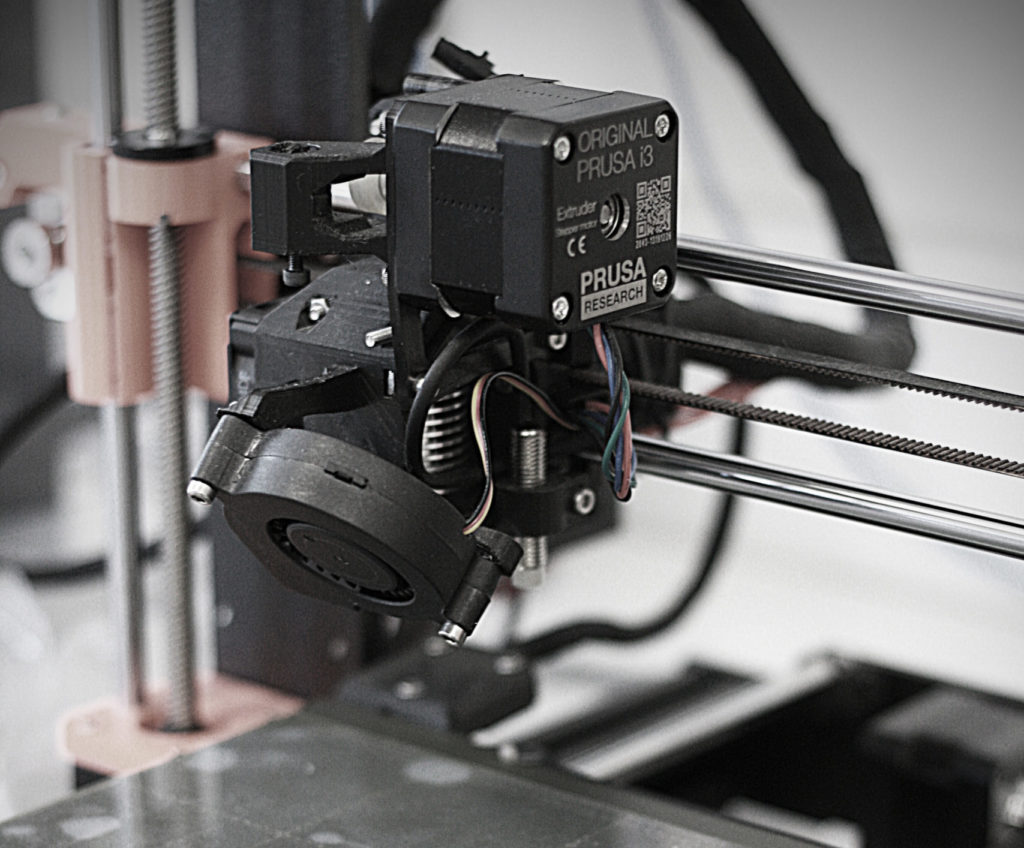

3D printing and especially Fused Filament Fabrication (FFF) technology for composite materials reinforced by continuous fibers is an emerging research field which aims to enhance the mechanical performance of 3D printing structures and to widen the field of application (aerospace, sailing…). Another trend, 3D printing allows to develop stimulable materials (sensor and/or actuators) and to consider parts with complex architecture that can be deployed under various stimulation (electricity temperature, pressure…). The present work is therefore part of this context and aims to develop new multi-functional materials elaborated by 4D printing. First, the scientific objective of this work is to better understand the relationship between the process, the induced microstructure, mechanical and the hygromechanical performances in order to target structural applications (aeronautic, sailing) for composite materials reinforced with synthetic fibers (carbon and glass) and natural fibers (flax). The second part of this work aimed to develop hygromorphic composites reinforced with continuous fibers (synthetic and natural) with a bioinspired bilayer architecture inspired by the pinecone scale. The conductive behavior of carbon fiber was used to create new electrothermo- hygromorph actuators with controlled and accelerated actuation compared to conventional hygromorphs. Finally, the design freedom provided by 4D printing made it possible to control the local stiffness and actuation of composite actuators reinforced with continuous flax fibers.