Available online !! New paper related to 3D Printing of Bio-Composites ! Check this out !

Tailoring the mechanical properties of 3D-printed continuous flax/PLA biocomposites by controlling the slicing parameters, Composites Part B: Engineering, Volume 203, 2020, 108474, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2020.108474

Authors: A. Le Duigou, G. Chabaud, R. Matsuzaki, M. Castro

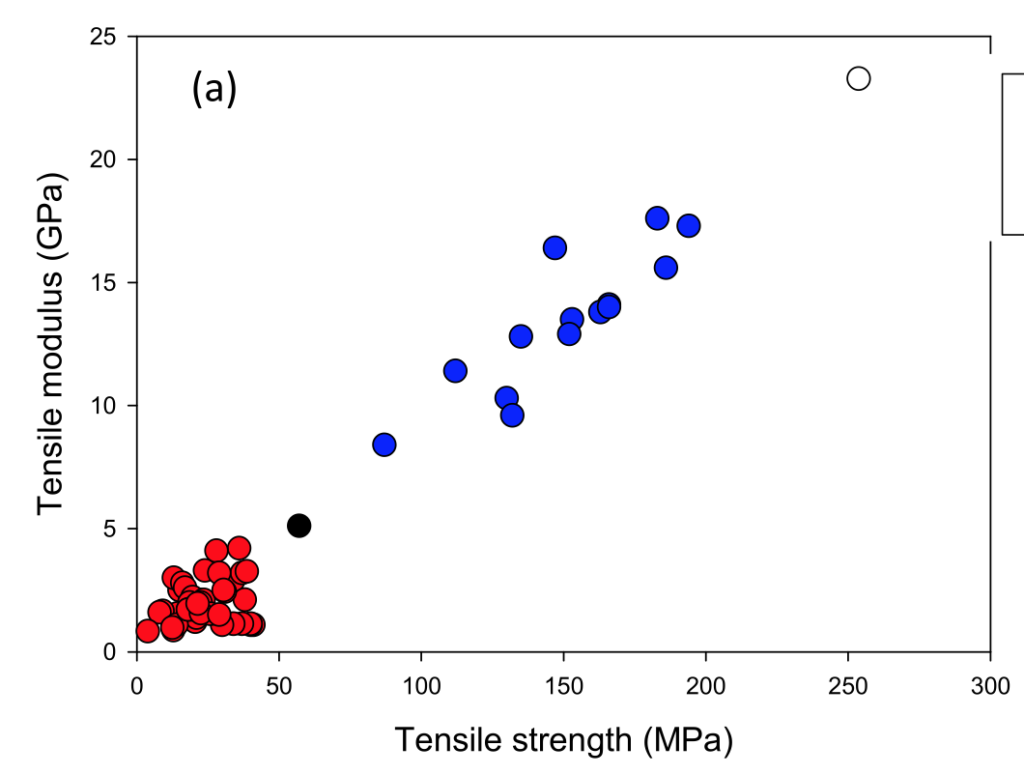

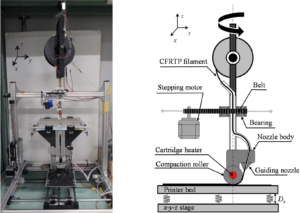

Abstract: D printing represents a great opportunity for biocomposites to be developed for the first time on the same time scale as their synthetic counterparts. The purpose of this article is a global investigation of the relationship between slicing parameters (i.e. Layer Height (LH), Interfilament Distance (ID), Number of Trips (NT), Number of Layers (NL)), microstructure and induced tensile properties in order to propose 3D printed continuous flax/PLA biocomposites with tailored mechanical properties.

The Layer Height controls filament compaction during printing. The decrease in LH from 0.6 to 0.2 mm results in a reduction in layer thickness, a decrease in porosity, and an increase in tensile properties (+210% for stiffness and strength). The increase in NL from 1 to 10 results in higher compaction ratio due to the compaction effect of layer n on layer n-1 and superior tensile properties (+50% in modulus and +73% in strength).

NT and ID control the space available for the filament between the nozzle and adjacent filaments respectively. This significantly affects the average layer thickness and the overall geometry of the sample. Increasing NT from 1 to 18 reduces the space available for the polymer matrix flow for each filament due to the neighboring effect. Generally, the 3D printing process with continuous-flax/PLA composites provides a wide range of tensile properties that are still considerably higher than the current published values for printed short natural fiber composites and in the same range as printed continuous glass fiber/PA composites.