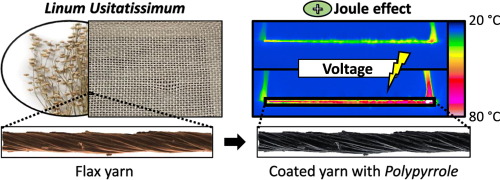

🎉 Congratulations to Alaa Ismael on the publication of her first paper! This paper by Alaa Ismael et al. is entitled ” Conductive and thermoactivated flax yarns developed by in situ polypyrrole polymerizations: Interactions with carbohydrate polymers” and published in Progress in Organic Coatings (IF 6.7) https://doi.org/10.1016/j.porgcoat.2024.108894.

This is a huge milestone in her academic journey, and it’s inspiring to see her hard work, dedication, and passion for research come to fruition. Publishing a first paper is no small achievement, and it’s a testament to your intellectual curiosity and perseverance. Wishing you continued success as you continue to make valuable contributions to our project field. Keep up the amazing work! 🚀📚

This work is performed within the frame of REDeSIGN project. The teams gratefully acknowledge the funding received from ANR (Agence Nationale de la Recherche), France, for the REDeSIGN project (ANR-21-CE10-0011)

Highlights

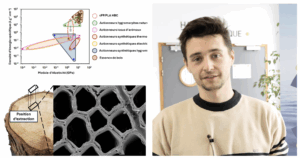

•Flax yarns properties are retained differently after two in-situ polymer coatings.

•Different content of coated polymers results in varied electrothermal properties.

•In situ polymerization induces hydrolysis of non-cellulosic polymers in flax.

•Lower biochemical loss correlates with higher mechanical and hygroscopic properties.

Full abstract: This study investigated the functionalization of flax yarn via in situ chemical polymerization of conductive polypyrrole (FY-PPy) and polypyrrole‑silver (FY-PPy-Ag). Voltage-controlled experiments were conducted to assess the electrothermal properties of the modified yarns, with a focus on the Joule effect. FY-PPy exhibited significantly higher electrical conductivity (826 S.m−1) and thermal conductivity (8583 J.S−1 m−1.°C−1) than FY-PPy-Ag did, which had values of 505 S.m−1 and 5616 J.S−1 m−1.°C−1, respectively. This enhanced conductivity resulted in a greater temperature increase during Joule heating, with the superior electrothermal performance of FY-PPy linked to the coated material formed during polymerization. Quantitative assessments of the coated conductive material were performed, revealing 25.5 wt% of PPy in the FY-PPy sample and 16.5 wt% of PPy and 26.1 wt% of silver in the FY-PPy-Ag sample. Gas chromatography tests revealed that the cellulosic content of the initial yarn remained unchanged after both functionalization methods were applied; however, the non-cellulosic polysaccharide content decreased significantly due to acidic treatment. Longitudinal tensile tests and sorption–desorption characterizations indicated that FY-PPy retained properties closer to those of the unfunctionalized yarn, whereas FY-PPy-Ag exhibited greater property loss. Our findings provide essential insights into the enhanced characteristics of functionalized flax yarns, highlighting their potential applications in the advanced electronics and composite industries.