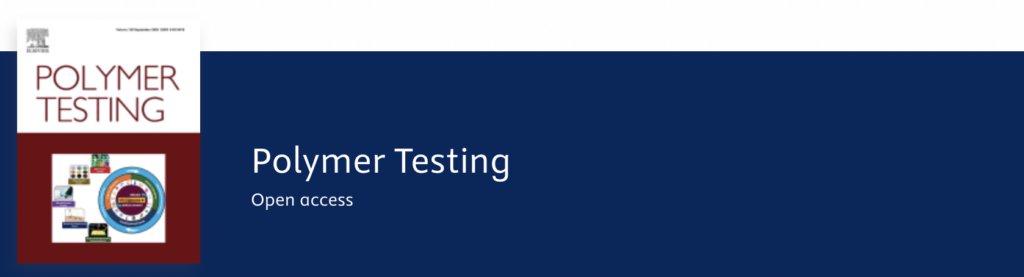

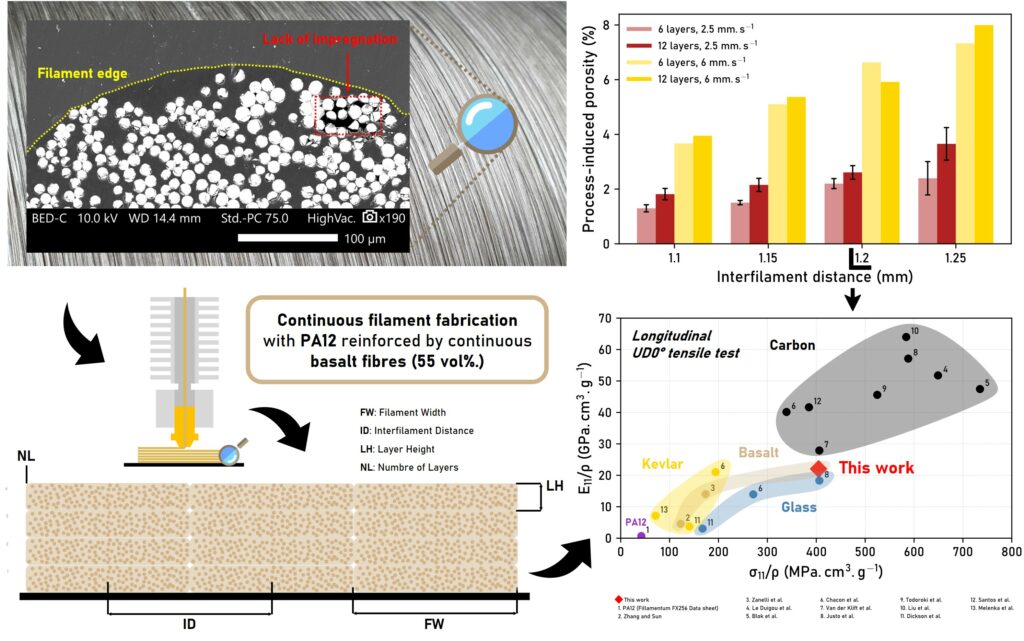

🚀 Excited to share our latest research on 3D-printed composites with continuous basalt fibres! 🔬 We explored continuous filament fabrication (CFF) using basalt fibres in a PA12 matrix, achieving a 55% fibre volume fraction. 📉 By optimizing slicing parameters, we reduced process-induced porosity to just 2.15%, ensuring high material quality. 💪 The composites exhibited competitive mechanical performance in the fibre direction, on par with glass-fibre counterparts. 🌑 With basalt as a strong analogue for lunar regolith, this work also paves the way for out-of-Earth manufacturing applications.

P.L. Pichard, T. Le Gagne, L. Maheo, J. Dirrenberger, U. Lafont, A. Le Duigou, 3D printing strategies and mechanical performance assessment of continuous basalt-fibre/PA12 composites with high fibre volume fraction, Polymer Testing, Volume 150, 2025, 108936, ISSN 0142-9418, https://doi.org/10.1016/j.polymertesting.2025.108936.

Additive manufacturing:

-

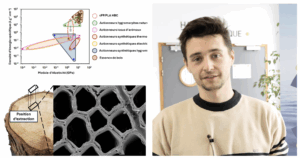

Characterization of morphological, thermal and tensile properties of a filament loaded with 55 vol% of continuous basalt fibres, for the continuous filament fabrication technology (CFF).

-

Determination of slicing parameters and printing parameters for the filament. Parameter optimisation leads to a minimum of pore volume fraction of 2.15 % (as measured by SEM image analysis).

-

Extensive in-plane characterization of the mechanical properties (longitudinal tension and compression, transverse tension and in-plane shear) and comparison with existing CFF-printed parts, including damage investigation.

-

Measurement of the coefficient of thermal expansion (CTE) in longitudinal, transverse and out-of-plane directions